In industrial processes where fluid flow measurement is critical, flow meters play a central role in maintaining accuracy, efficiency, and compliance. However, like any precision instrument, flow meters can drift over time due to environmental conditions, mechanical stress, or wear and tear. Regular calibration is necessary to ensure their accuracy — and that’s where on-site flow meter calibration becomes invaluable.

On-site calibration offers a practical, time-saving, and cost-effective alternative to removing meters and sending them to a lab. This article explores the importance, process, benefits, and best practices of on-site flow meter calibration across various industries.

What is On-Site Flow Meter Calibration?

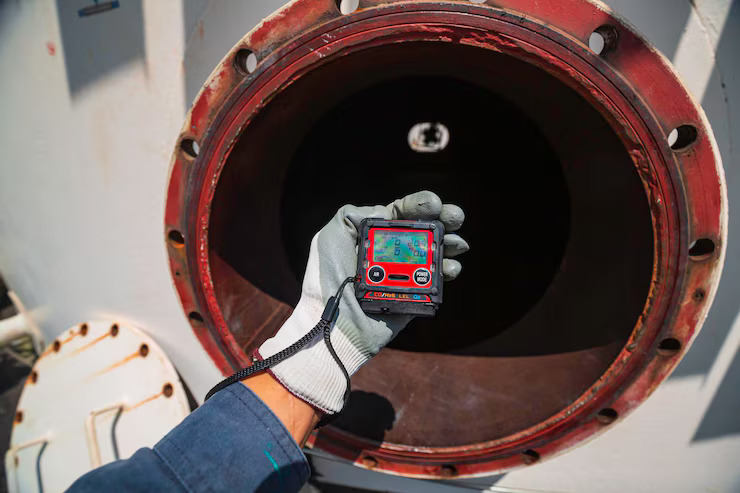

On-site calibration is the process of checking and adjusting flow meter accuracy at the actual location where the meter is installed, without the need to remove or disrupt the equipment. Portable calibration devices or reference meters are used to compare the performance of the flow meter against known standards.

It is commonly used in:

- Water treatment plants

- Oil and gas pipelines

- Food and beverage industries

- Chemical manufacturing

- Pharmaceutical facilities

- HVAC systems

On-site calibration is especially valuable when downtime is costly or when equipment is installed in hard-to-reach or hazardous areas.

Why Is Flow Meter Calibration Necessary?

Flow meters are used to measure the volume or mass of a fluid moving through a pipeline. Accurate measurements are critical for:

- Product quality control

- Billing and custody transfer

- Regulatory compliance

- Process optimization

- Safety monitoring

Over time, factors such as temperature fluctuations, vibration, corrosion, or clogging can affect the accuracy of flow meters. Without regular calibration, even a small error can result in large financial or operational losses.

Key Benefits of On-Site Calibration

Minimal Downtime

Calibration can be performed during regular operations or brief shutdowns, significantly reducing production interruptions.

Cost Savings

Avoids transportation, reinstallation, and downtime costs associated with off-site calibration.

Real-World Accuracy

Calibrating in the actual operating environment allows for more realistic and accurate adjustments, considering temperature, pressure, and fluid characteristics.

Immediate Adjustments

Technicians can quickly identify and correct errors, reducing the risk of prolonged inaccuracies.

Compliance and Documentation

Certified calibration records help meet industry standards such as ISO/IEC 17025, API, ASTM, and government regulations.

On-Site Calibration Process

1. Preparation and Inspection

Technicians begin with a visual inspection of the flow meter, checking for leaks, damage, and correct installation. Operational data such as fluid type, flow rate, and environmental conditions are recorded.

2. Reference Setup

A calibrated portable master meter, prover, or ultrasonic flow meter is connected in series with the flow meter under test. These reference devices are traceable to national or international standards.

3. Testing

Fluid is passed through both meters at various flow rates. The output readings are recorded and compared to identify any discrepancies.

4. Adjustment

If errors exceed acceptable limits (typically ±0.5% or less), adjustments are made either through the meter’s software or via correction factors.

5. Certification

Once calibrated, the technician provides a calibration certificate detailing the procedure, equipment used, measurement results, error analysis, and traceability.

Types of Flow Meters That Can Be Calibrated On-Site

- Electromagnetic Flow Meters (Magmeters)

- Ultrasonic Flow Meters

- Turbine Flow Meters

- Coriolis Mass Flow Meters

- Positive Displacement Meters

- Differential Pressure Flow Meters

Most modern meters are equipped with diagnostic tools or digital interfaces that facilitate easy calibration and data logging on-site.

Industries Benefiting from On-Site Calibration

Manufacturing & Process Industries

Ensures accurate fluid dosing, mixing, and batching for product consistency.

Oil & Gas

Vital for custody transfer and pipeline flow monitoring, where even minor errors can mean large financial losses.

Water & Wastewater Management

Maintains regulatory compliance and proper billing for municipal and industrial water systems.

Food & Beverage

Crucial for fluid transfer, bottling, and cleaning-in-place (CIP) operations.

Pharmaceutical

Required for precision liquid handling under stringent FDA and GMP standards.

Best Practices for On-Site Flow Meter Calibration

- Schedule Regular Calibration: Follow manufacturer recommendations or industry standards (usually annually or semi-annually).

- Use Certified Technicians: Only qualified personnel with traceable reference equipment should perform calibration.

- Keep Detailed Records: Store all certificates and data for audits, quality control, and compliance.

- Consider Environmental Conditions: Account for actual fluid type, temperature, and pressure during calibration.

- Audit Flow Meter Performance: Periodically assess long-term drift or damage and consider upgrading or replacing older meters.

Choosing a Reliable On-Site Calibration Service

When selecting a calibration service provider, look for:

- Accreditation (such as ISO/IEC 17025)

- Use of traceable and certified equipment

- Industry-specific expertise

- Fast turnaround and responsive customer support

- Clear documentation and after-service support

Conclusion

On-site flow meter calibration is an efficient, accurate, and economical solution for industries that rely on precise fluid measurement. It helps maintain operational integrity, ensures compliance, and minimizes costly downtime. As technology evolves and the demand for real-time accuracy increases, on-site calibration continues to gain importance across all sectors.

Whether for manufacturing, water distribution, or critical process control, investing in regular on-site calibration is not just good practice — it’s a strategic necessity.